KVIC model

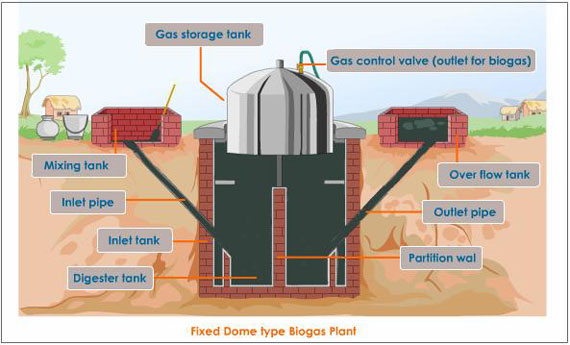

This mainly consists of a digester or pit for fermentation and a floating drum for the collection of gas. Digester is 3.5-6.5 m in depth and 1.2 to 1.6 m in diameter. There is a partition wall in the center, which divides the digester vertically and submerges in the slurry when it is full.

The digester is connected to the inlet and outlet by two pipes. Through the inlet, the dung is mixed with water (4:5) and loaded into the digester. The fermented material will flow out through outlet pipe. The outlet is generally connected to a compost pit. The gas generation takes place slowly and in two stages.

In the first stage, the complex, organic substances contained in the waste are acted upon by a certain kind of bacteria, called acid formers and broken up into small-chain simple acids.

In the second stage, these acids are acted upon by another kind of bacteria, called methane formers and produce methane and carbon dioxide.

The gas holder is a drum constructed of mild steel sheets. This is cylindrical in shape with concave. The top is supported radically with angular iron. The holder fits into the digester like a stopper. It sinks into the slurry due to its own weight and rests upon the ring constructed for this purpose. When gas is generated the holder rises and floats freely on the surface of slurry. A central guide pipe is provided to prevent the holder from tilting. The holder also acts as a seal for the gas.

The cost of drum is about 40% of total cost of plant. It requires periodical maintenance. The unit cost of KVIC model with a capacity of 2 m3/day costs approximately Rs.14, 000 .